Festo: What the world's first pneumatic cobot can do

Following the announcement, the presentation of the new Cobot has just taken place. Dr. Melzer (photo left), Chief Technology Officer at Festo praised the Cobot more than necessary. You could tell he believes in it. "Clear innovation leap in automation technology, which we are all proud of," were his words. The Cobot has a payload of 3 kg and a reach of 670 mm bid a repeatability of 0.3 mm. The 3 kg limit is remarkable, as this payload is the lower limit for other manufacturers (e.g. UR 3). The pneumatics are said to increase productivity and, according to the press release, "The direct drives in the joints are more cost-effective and especially lightweight because, unlike electric solutions, no heavy gears and expensive force-torque sensors are needed." Contrary to my speculation, the Cobot does not exhaust the possibilities of artificial intelligence.

Robotics Director Christian Tarragona (photo, right) spoke of five guiding principles during development:

- Designed ease of use

- Created for easy movement

- Shaped for easy integration

- Development for economic success

- Inventend for easy collaboration

In terms of price, the Festo Cobot is to be positioned somewhat more favorably than the electric Cobot. The robot is operated with air. This gives new possibilities after a collision or even when assembling parts.

Simple programming

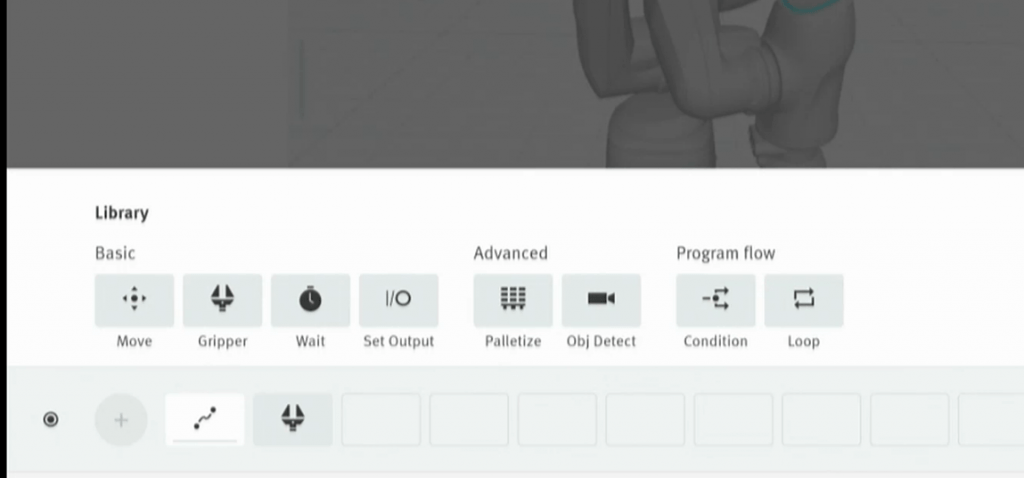

It is programmed by means of manual guidance, buttons on the arm and with the help of icons on the tablet. The corresponding demonstration of the simplicity of operation was reminiscent of Franka Emika's demonstration. However, it is necessary to be honest: Programming by means of manual guidance of the robot arm and button operation was a big deal back then and can hardly be simplified any further. In this respect, simplicity of programming is only a selling point compared to cobots, which are less comfortable. The picture shows the well-known icon programming:

But no matter, the Festo is also so innovative.

No control cabinet

On the other hand, the elimination of the previously required control cabinet or the compression of all units in the somewhat more voluminous Festo-Cobot is very innovative. Its base seemed very massive. The elimination of the "control cabinet" as well as the weight of less than 20 kg of the Cobot make it flexible. It can be transported more easily. However, if the workstation has to be changed more frequently, a cobot is usually moved on a trolley. There would also be space for the switching unit.

Gentle collisions

As with the programming, which is not super-innovative but still at the most modern level, the degree of innovation also applies to any collisions. These run smoothly, but are not automatically avoided.

Very valuable appearance

For me, a real highlight is the appearance of the Cobot. It doesn't look like a work tool, but almost as classy as a luxury car.

Late market launch

Although the Cobot will be presented at the Hannover Messe, it will not be introduced to the broad market until 2023. It will be distributed via Festo sales. This can become a problem because Festo has a huge product range. It is known from Omron that their Cobot distribution is dependent on the respective employee.

Conclusion

Unless other market players make a big splash or occupy markets until the Festo cobot is launched, the cobot will certainly be successful - in its segment. It will apparently be cheaper than an electric cobot, although Festo has a very good image, it is modern and also looks very good. This should make it extremely attractive and give it competition from Franka, for example. Larger models have already been announced. The focus is on the range and not the payload.

Are we networking? LinkedIn

-> To the Cobot group on LinkedIn (Link) .

In my own right/advertisement

The author of this blog is significantly involved in the AI/robotics project Opdra. He advises robotics companies and investors on market analysis and funding/subsidies. More about him can be found here.