Humanoide Roboter: Warum sie „wenig“ kosten können

Geht es um humanoide Roboter lautet ein Einwand schnell, dass sie so komplex sind, dass sie unbezahlbar sein werden bzw. sich zumindest nicht rechnen können. Ob der Tesla Optimus tatsächlich für 20.000 $ angeboten wird, sei dahingestellt. Aber auch wenn er z.B. 30.000 $ kosten sollte, wäre er preislich m.E. attraktiv. Denn solch ein humanoider Roboter könnte im Ideal z.B. im Schichtbetrieb einen menschlichen Arbeitsplatz ohne Umbauten übernehmen.

Besuchen Sie den Deutschen Robotikverband für mehr Informationen.

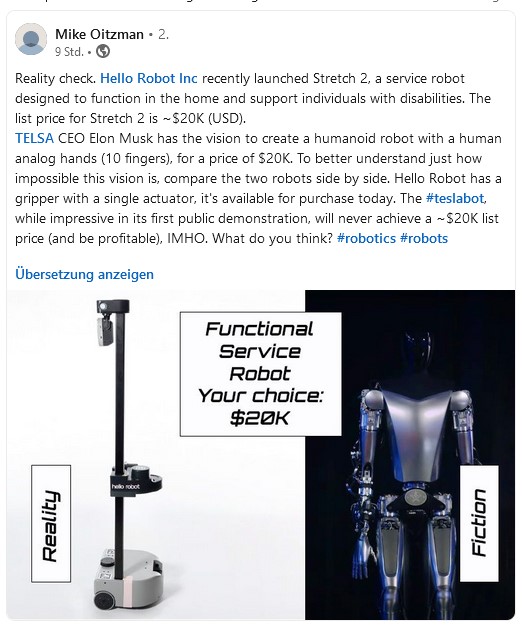

Ist aber ein Preis jenseits den Werten, die z.B. Boston Dynamics aufruft oder die der „Bauch“ erwarten läßt, realistisch? Dieser LinkedIn-Autor hat so seine Zweifel und er ist sicherlich nicht allein:

Die Automobilindustrie zeigt wie es geht

Der oben abgebildete Roboter von Hello Robot dürfte in kleinen Stückzahlen hergestellt werden. Dies gilt für viele Roboter. Im Idealfall mag ihre Fertigung zu einem beachtlichen Teil automatisiert sein, aber die verbauten Teile werden doch in kleinen Stückzahlen hergestellt. Ähnliches gibt es auch in der Automobilindustrie. Im Zuge eines Forschungsprojektes habe ich den BMW-Werkzeugbau kennengelernt. In einer riesigen Halle werden dort die Werkzeuge für die BMW-Werke hergestellt. Wird eine Kühlhaube gestanzt, geschieht dies in einer Form, die der Werkzeugbau hergestellt hat. Alles mit größter Genauigkeit damit die Kühlerhaube auch glatt ist und dies auch nach 500.000 Pressvorgängen. Entsprechend teuer ist die Herstellung eines Werkzeuges. Im Bewußtsein dessen habe ich den Leiter gefragt, ob der Aufwand für klein-volumige Hersteller wie Ferrari & Co. nicht viel zu groß sei. Er bejahte und sagte, dass dort die Teile individuell gelasert oder sonstwie gefertigt werden und viel Handarbeit dabei wäre. Es fehlen halt die Stückzahlen.

Dies brachte mich auf die Idee einmal Ferrari mit Porsche zu vergleichen. Ich kenne beide Marken nicht gut, sehe hier aber den Unterschied zwischen Einzel- und Serienfertigung. Ob ein Ferrari tatsächlich hochwertiger als ein teurer Porsche ist, kann ich nicht beurteilen. Der Ferrari mag den stärkeren Motor haben, der Porsche aber vermutlich mehr Assistenzsysteme. Die erhöhen die Komplexität bei der Fertigung und kosten durchaus einiges. Also wagen wir den Vergleich bei den Stückkosten. Die Zahlen wurden nur schnell gegooglt und stellen keine wissenschaftliche Arbeit dar:

Die Kosten eines Ferraris liegen somit um rund den Faktor 3 über dem eines Porsches. Wer Ferrari liebt, wird sagen ein Porsche ist halt doch wesentlich schlechter. Ok, um dies zu berücksichtigen kann man die Porsche-Kosten um horrende z.B. 60.000 € erhöhen. Dann hat Ferrari noch immer einen Mindermengen-Nachteil in Höhe des Faktors 2.

Mittelfristig können Humanoide in ganz anderen Stückzahlen produziert werden

Bei den Porsche-Zahlen gilt es zu berücksichtigen, dass das Unternehmen viele verschiedene Modelle und Antriebe hat. Porsche profitiert zwar von der Plattformstrategie des VW-Konzerns, aber die produzierten 146.000 Stück verteilen sich auf etwa 10 Modelle mit vielen Varianten. Ein richtig in Serie gehender Humanoider Roboter kann schnell eine sechsstellie Jahresfertigung erreichen. Und im Gegensatz zu einem Porsche besteht er aus weniger Materialien und auch nicht aus hochwertigstem Leder. Daher halte ich einen Preis von deutlich unter 50.000 € für absolut realistisch.

Ohne Autonomes Fahren werden Humanoide teurer

Die letzten Wochen hat sich immer mehr herausgestellt dass echtes autonomes Fahren auf sehr lange Zeit nicht machbar sein wird. Als regelrecht ernüchternd fand ich diesen Kommentar im Handelsblatt. Er ist voll mit für mich neuem Wissen. Meine Vision lautete, inspiriert durch das Video, bis dahin: Paketauto fährt autonom, humanoider Roboter steigt aus und bringt die Pakete. Würde dies gehen, könnten weltweit schnell Mio. Humanoide eingesetzt werden.

Vernetzen wir uns? LinkedIn

-> Zur Cobot-Gruppe auf LinkedIn (Link)

In eigener Sache/ Werbung

Der Autor dieses Blogs ist maßgeblich am KI-/ Robotik-Projekt Opdra beteiligt. Er beantwortet Unternehmen die Frage, ob und wie ein Roboter bei Ihnen eingesetzt werden könnte (Erstanalyse samt Empfehlung). Dies in den Großräumen Trier und Lüneburg sowie Ostdeutschland ohne Leipzig/ Berlin für 700 € netto, im restlichen Deutschland zu einem Pauschalpreis von 1.750 € netto (incl. Anreise). Der niedrige Preis ist dank Förderung möglich. Permanent auf der Suche nach interessanten Lösungen hat er schon hunderte Applikationen gesehen. Aus diesem Grund gehören auch Großunternehmen zu seinen Kunden, die zwar über Know how verfügen, aber nicht den gesamten Markt kennen. Für Unternehmen ab 250 Mitarbeitern oder solchen mit Sitz in Österreich oder Schweiz gilt der Pauschalpreis nicht. Mehr zu seiner Person finden Sie hier.

Wer es bis hierhin ausgehalten hat, verdient eine Belohnung. Der schönste Autovergleich, den ich kenne:

Besuchen Sie den Deutschen Robotikverband für mehr Informationen.