Schmalz mit Spezialgreifern für Batteriezellfertigung

Wenn ich Linkedin richtig verfolgt haben, fanden die Aktivitäten rund um die Batteriezelle der Firmen Omron und Daussault bei der Hannover Messe große Aufmerksamkeit. Schmalz hat eine Greifer-Lösung für die schonende Behandlung von Batterien vorgestellt. Hier die Pressemitteilung:

Besuchen Sie den Deutschen Robotikverband für mehr Informationen.

Samthandschuhe für Batterien

Sie werden beschmiert, gewalzt und gekappt – der Weg klingt hart, den Kupfer- und Alufolien hinter sich bringen müssen, bis sie ihre Rolle als Anode und Kathode in einer Batterie ausüben können. Umso sanfter muss die Handhabung zwischen den einzelnen Produktionsschritten sein – wie gelingt das?

Bereits seit 2009 fördert die Regierung die Elektromobilität. Auch die Entwicklung und Fertigung von Batterietechnologie wird vorangetrieben: Wirtschaft und Politik arbeiten daran, das Know-how zur Entwicklung und Fertigung auf- und auszubauen. Dass eine wirtschaftliche Batteriezellproduktion in Deutschland möglich ist, bekräftigte Dr. Michael Meister, Parlamentarischer Staatssekretär der Bundesministerin für Bildung und Forschung, 2021 auf dem „Batterieforum Deutschland“. Meldungen deutscher Automobilhersteller über Kooperationen, eigene Forschungslabore und Testbetriebe zur Serienproduktion bestätigen dies. Neben dem Einsatz in E-Autos sind Batterien ebenso wichtig für den Alltag. Vom Akkuschrauber über E-Bikes bis zum Smartphone – der Strom „to go“ ist nicht mehr wegzudenken. Ebenso relevant ist die stationäre Anwendung, zum Beispiel um regenerativ erzeugte Energie zu puffern.

Jede Anwendung stellt eigene Anforderungen an die Batterietechnologie. Doch für die Herstellung ist der spätere Einsatz zweitrangig – denn hier müssen in jedem Fall größte Sorgfalt und Präzision mit einer wettbewerbsfähigen Zellfertigung in Einklang gebracht werden. Unersetzlich sind dabei die kleinen Helfer, die einen schonenden Transport der empfindlichen Kathoden, Anoden, Separatoren und Pouchzellen ermöglichen: Spezialgreifer und Endeffektoren der J. Schmalz GmbH.

Vom Pulver zur Pouch

Zwei Pasten und zwei Metallfolien bilden die Basis einer jeden Antriebsbatterie. Für die Anode wird eine Graphitmasse auf eine Kupferfolie gestrichen. Die Kathode besteht aus einer Aluminiumfolie, auf die eine Metalloxid-Mischung aus Nickel, Kobald, Mangan und Lithium aufgetragen wird. Die beidseitig beschichteten Folien werden getrocknet, kalandriert und zurechtgeschnitten. Jetzt sind sie bereit fürs Stapeln. „Wir empfehlen hierfür die Spezialgreifer STGG, da sie hochdynamisch mit den sensiblen Folien umgehen können“, erklärt Dr. Maik Fiedler, Leiter der Geschäftsbereiche Vakuum-Automation und Vakuum-Handhabung (Foto oben). Der STGG greift abwechselnd Anode, Separator, Kathode und wieder Separator, um sie aufeinander abzulegen. Die Geschwindigkeit steht hier ebenso im Fokus wie die präzise Positionierung. Dabei darf der Greifer keine Abdrücke hinterlassen und nicht die empfindliche Beschichtung kontaminieren. „Unsere Lösung heißt PEEK“, sagt Dr. Fiedler. Schmalz fertigt aus dem chemisch hochbeständigen Polyetheretherketon eine Saugplatte mit vielen kleinen Löchern, die vollflächig greift. Die ebene Fläche minimiert die Flächenpressung. Die aktive Abblasfunktion des STGG beschleunigt den Pick & Place-Prozess, während der hohe Volumenstrom Partikelrückstände auf den Elektroden verhindert. Eine pneumatische Vakuum-Erzeugung ohne bewegte Teile macht den Spezialgreifer rein- und trockenraumtauglich.

Auch für das Vereinzeln und Ablegen der dünnen Separatorfolien eignet der Spezialgreifer STGG. Separatoren bestehen meist aus sehr feinporigen biegeschlaffen Kunststoffen oder Vliesen. Sie trennen Anode und Kathode räumlich voneinander und verhindern einen Kurzschluss. Gleichzeitig sind sie durchlässig für die positiven Lithium-Ionen, die beim Entladen von der Anode zur Kathode strömen und beim Laden wieder zurückwandern. „Der STGG arbeitet mit einem hohen Volumenstrom und greift dadurch auch poröse Materialien sicher“, erläutert Dr. Fiedler. Die ESD-konforme Oberfläche leitet zudem elektrostatische Aufladung zuverlässig ab und schützt so vor ungewünschter Adhäsion.

Zelle für Zelle

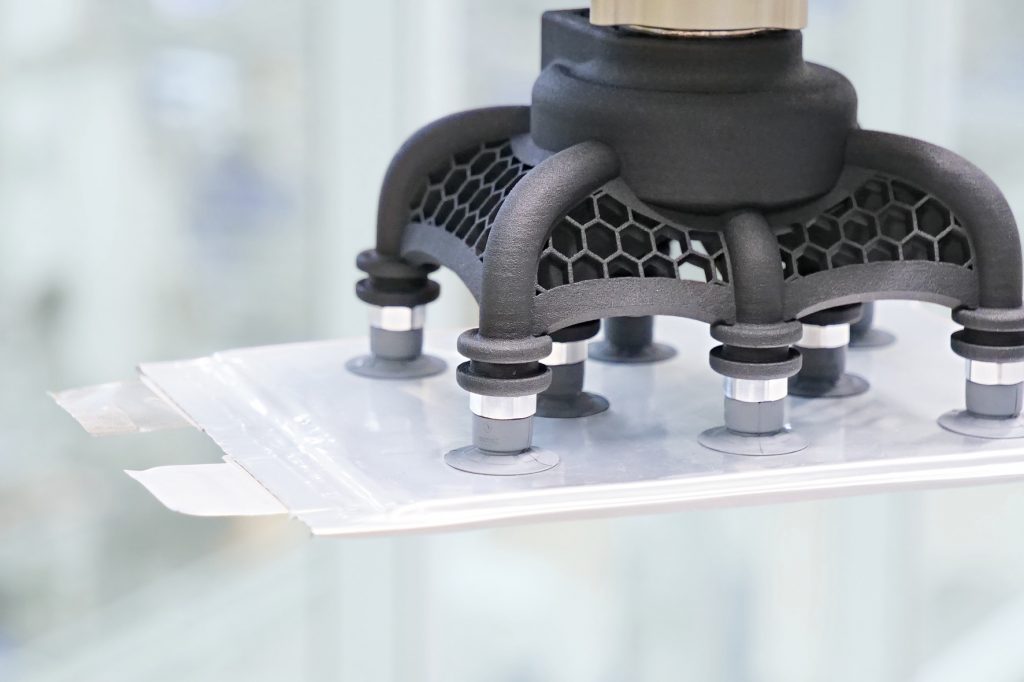

Ist der Zellstapel fertig, werden die überstehenden Leiterfähnchen gekürzt und der Stapel in eine Pouchfolie gepackt. Rundum versiegelt, ist die sogenannte Pouchzelle bereit für die Elektrolyt-Injektion. „Die Pouchzellen sind empfindlich und dürfen keinesfalls durch den Greifer deformiert werden. Zudem können sie je nach Einsatz in der Form variieren“, erklärt Dr. Fiedler. Für jede Geometrie passend ist der Leichtbaugreifer SLG. Schmalz fertigt ihn additiv, nachdem der Kunde ihn online konfiguriert hat, und garantiert somit kurze Lieferzeiten. Damit die Aluminiumverbundfolie der Pouchzelle beim Greifen nicht tiefgezogen wird, kommen strukturierte Sauger der SFF- oder SFB1-Reihe zum Einsatz. Beide Varianten kombinieren Abstützflächen in Form von Waben auf der Saugfläche mit einer weichen und besonders flachen Dichtlippe. Dadurch können sie sanft und dennoch mit einer hohen Saugraft zupacken, ohne die Oberfläche der Pouchzelle zu verformen.

Ebenso wichtig wie Material, Geometrie und Größe des Greifers ist das Vakuum. Wie und wo es erzeugt wird, ist der Schlüssel für eine hochdynamische und zugleich absolut sichere Handhabung. „Unsere dezentralen Vakuum-Erzeuger der SCPM-Baureihe erfüllen alle diese Anforderungen. Sie sind kompakt und zugleich saugstark“, sagt Dr. Fiedler. Sie sind so klein, dass sie nah am Sauggreifer montiert werden können und damit Leistungsverluste minimieren. Das Ventil des Kompaktejektors schließt, wenn kein Strom anliegt. Damit hält der Greifer die Batteriezelle sicher, auch wenn die Energie ausfällt. „Ein weiterer Vorteil ist, dass Anwender spezielle Funktionen in das System integrieren können, wie eine redundante Vakuum-Erzeugung oder Werkstückerkennung“, ergänzt Dr. Fiedler.

Das passende Handhabungssystem platziert die einzelnen Zellen in ein Modul, wo sie in Reihe oder parallel verschaltet werden. Mehrere Module ergeben ein Batteriepack, das je nach Hersteller und Fahrzeugkategorie weniger oder mehr Pouchzellen vereint.

Rund statt flach

Der Vorteil von Pouchzellen ist, dass sie flach bauen und damit die Wärme gut abgeben können. Sie sind vielseitig und nutzen das vorhandene Volumen in einem Batteriemodul optimal aus. Ihr Nachteil: Die Hülle ist empfindlich und schützt die Anoden, Kathoden und Separatoren nicht vor mechanischen Einflüssen. Zudem besteht die Gefahr, dass sie sich zum Beispiel durch Alterungsprozesse aufblähen. In einigen Elektroautos sowie in Unterhaltungselektronik, E-Bikes und Werkzeugen kommen daher oft zylindrische Hard-Case-Zellen zum Einsatz. „Für die Handhabung von Rundzellen in der Modulmontage müssen wir den Anwendern Greifer anbieten, die sie frei konfigurieren können. Je nachdem, wie groß die einzelnen Zellen im Durchmesser sind, in welcher Anordnung und wie viele gegriffen werden sollen“, beschreibt Dr. Maik Fiedler. „Dank 3D-Druck ist das ab Losgröße eins problemlos möglich.“ Wählt der Anwender Sauger aus dem abdruckarmen Spezialwerkstoff HT1, kann er die Zellen direkt am Pol greifen – das Material wirkt zugleich als Isolator. So werden auch geladene Zellen sicher positioniert. Wichtig ist auch hier ein hoher Volumenstrom für den schnellen und sauberen Pick-&-Place-Prozess. „Hier punkten integrierte Vakuum-Erzeuger. Die Ejektoren verfügen über ein Sicherheitsventil, die auch ohne Strom das Vakuum aufrecht halten und damit die Handhabung absichern“, ergänzt Dr. Fiedler. Müssen die Rundzellen längs gegriffen werden, empfiehlt Schmalz Magnetgreifer SGM in der High-Performance-Version. Hier sichert ein Dauermagnet die Handhabung ab. „Sie sind kompakt, leicht und entwickeln dennoch hohe Haltekräfte“, zählt Dr. Fiedler die Vorteile auf. Diese greifen, solange die Batteriehülle ferromagnetisch ist.

Finale – vollautomatisch oder manuell

Jetzt ist es fast geschafft: Aus Folien wurden Zellen. Die Zellen sind in Modulen zusammengefasst, die nun in Batteriepacks verbunden und mit Kühlplatten, Verkabelungen und Elektronik komplettiert werden. „Flexibilität ist hier enorm wichtig. Die Speichergeometrien können sich ebenso unterscheiden wie Oberflächenstrukturen“, erklärt Dr. Maik Fiedler. Auch wenn die Module schwer sind, dürfen sie durch den Greifer nicht beschädigt werden – Vakuum schafft das. Der Flächengreifer FQE ist modular und für vollautomatisierte Pick-&-Place-Anwendungen ideal geeignet. Ebenso universal ist der Flächengreifer FMP. Sein Dichtschaum passt sich auch an strukturierte Oberflächen an. Beide sorgen mit ihrer energieeffizienten, integrierten Vakuum-Erzeugung für geringe Betriebskosten.

Bei den Arbeitsschritten, die nicht automatisiert sind, entlasten manuelle Hebehilfen wie der Vakuumheber JumboFlex die Monteure. Das können die Kühlmodule sein oder die Abdeckplatten, die am Ende manuell auf den Batteriegehäusen platziert werden müssen. Extra Sicherheit bietet die Safety+-Bedieneinheit: Das Zwei-Hand-Konzept zum Ablösen schützt besonders sensible Werkstücke beim Ablegen. Zudem kann die Absenkgeschwindigkeit reduziert werden.

Das Batteriepack ist nun bereit für die Dichteprüfung – Gehäuse und Kühlsystem dürfen keine Leckage aufweisen. Das Batteriemanagementsystem erhält die aktuellste Software, passend für den Autotyp, und der erste Lade-/Entladevorgang im Verbund erfolgt unter strenger Aufsicht. Sind Verkabelung und Elektronik in Ordnung und funktioniert das Batteriemanagement ebenso wie alle Subkomponenten, ist es geschafft. Nach dem Labeln mit Warnhinweisen und ID-Tags sind die Batterien fertig für den Transport. „Es ist ein langer und aufwendiger Weg vom Pulver zum fertigen Energiespeicher. Wir wissen, wie die Handhabung in jedem einzelnen Prozessschritt sicher gelingen kann und entwickeln für unsere Kunden passgenaue Lösungen “, sagt Dr. Maik Fiedler.

Vernetzen wir uns? LinkedIn

-> Zur Cobot-Gruppe auf LinkedIn (Link) .

In eigener Sache/ Werbung

Der Autor dieses Blogs ist maßgeblich am KI-/ Robotik-Projekt Opdra beteiligt. Er berät Robotik-Firmen und Investoren bei den Fragen Marktanalysen und Finanzierung/ Förderungen. Mehr zu seiner Person finden Sie hier.

Besuchen Sie den Deutschen Robotikverband für mehr Informationen.