ABB with smallest industrial robot to date - best-in-class payload

ABB is trying to occupy another interesting market. Specifically, it is about the range between the Mecademic with a payload of 0.5 kg and the usual 3 kg payload class. ABB does not want to follow competitors in the market, which is new for the company, but to set impulses right away, as the press release makes clear.

Highest precision with lower energy consumption

- New IRB 1010 designed to meet growing demand for portable smart devices

- Most precise robot in the 1.5-kg payload segment for highest manufacturing quality - 50 percent higher payload than comparable robots on the market

- 20 percent less energy consumption: OmniCore E10 controller enables manufacturers to improve energy efficiency and reduce costs

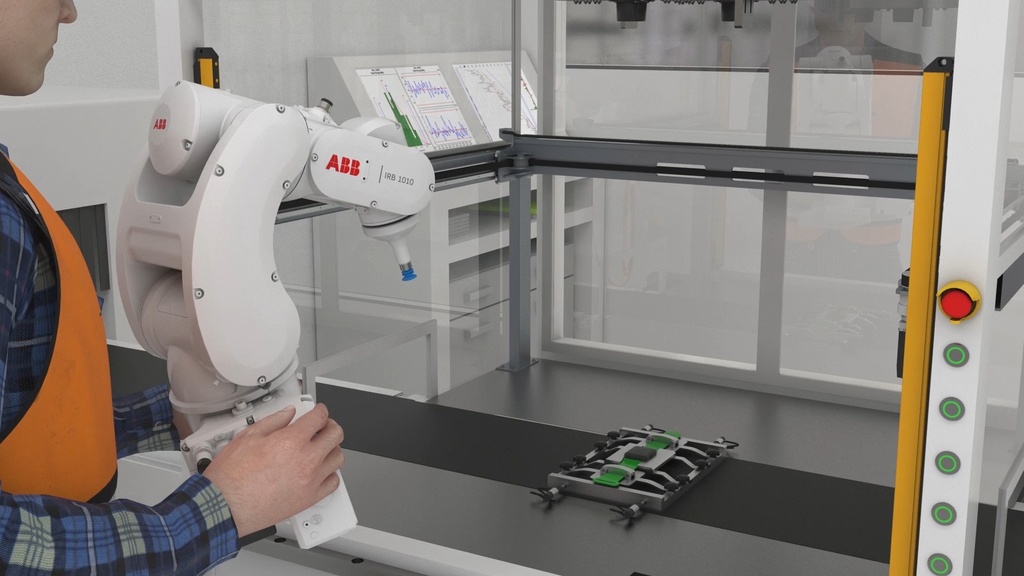

ABB has launched its smallest industrial robot to date. The IRB 1010 opens up new possibilities for faster, more flexible and high-quality production of wearable smart devices ("wearables"). With its compact size, best-in-class payload and unmatched precision, the IRB 1010 offers electronics manufacturers the opportunity to increase their production of devices such as smartwatches, headphones, sensors and health trackers through automation.

"The market for wearable smart devices is growing rapidly. Forecasts predict double-digit growth between 2022 and 2028," said Rui Liang, head of ABB Robotics' Electronics business line. "To meet this growth, companies need compact robotics solutions that can fit into the confined spaces of electronics manufacturing lines and accurately handle the small components that go into wearable devices. Our IRB 1010 is the most precise robot in its class for payloads up to 1.5 kilograms, and it meets these requirements. This allows companies to maximize throughput and productivity while ensuring the highest level of product quality."

Designed for tight spaces

The IRB 1010 was specially designed for tight spaces and special machines in electronics manufacturing. With a reach of 370 millimeters and a footprint of 135 x 250 millimeters, the IRB 1010 is 30 percent smaller than ABB's current smallest robot - the IRB 120. Thanks to these compact dimensions, more cells can be integrated into the production environment. This increases production density, which enables manufacturers to increase their output.

With up to 1.5 kilograms, the IRB 1010 has the highest payload in its class: It can handle up to three times more weight than comparable robots. Thanks to the high payload and a powerful compressed air supply, several objects can be handled simultaneously, allowing more objects to be processed per hour. It also opens up new application possibilities such as film peeling, material handling, assembly, gluing and inspection tasks.

6 Braking systems ensure extreme positional accuracy

Six braking systems provide a further boost to productivity. They enable the robot arm to remain in position even when stationary. This eliminates the time needed for the robot to resume its position after a stop or pause, and production can be resumed more quickly.

Accuracy of 0.01 mm

Key to the high precision of the IRB 1010 is ABB's OmniCore™ E10 controller. It features class-leading position repeatability and path accuracy of 0.01 millimeters. Its slim design makes it ideal for use in small parts assembly, where manufacturing cells must be ever smaller. The controller provides the flexibility needed to respond quickly to changing requirements, thanks to built-in digital connectivity and more than 1,000 additional functions that enable easy scalability. OmniCore E10 consumes up to 20 percent less energy than previous ABB IRC5C controllers. This gives manufacturers the opportunity to reduce energy costs and improve energy efficiency.

The impressive video represents the market expectation that ABB has. ABB is too big to be interested in niches.

(All photos ABB)

Are we networking? LinkedIn

-> To the Cobot group on LinkedIn (Link)

In my own account/advertisement

The author of this blog is significantly involved in the AI/robotics project Opdra. He advises SMEs around robotics - up to 50% funding for consulting is possible. Permanently looking for interesting solutions, he has seen hundreds of applications. For this reason, his customers also include large companies that have know-how but do not know the entire market. You can find more about him here.